Aspiration & Dosage

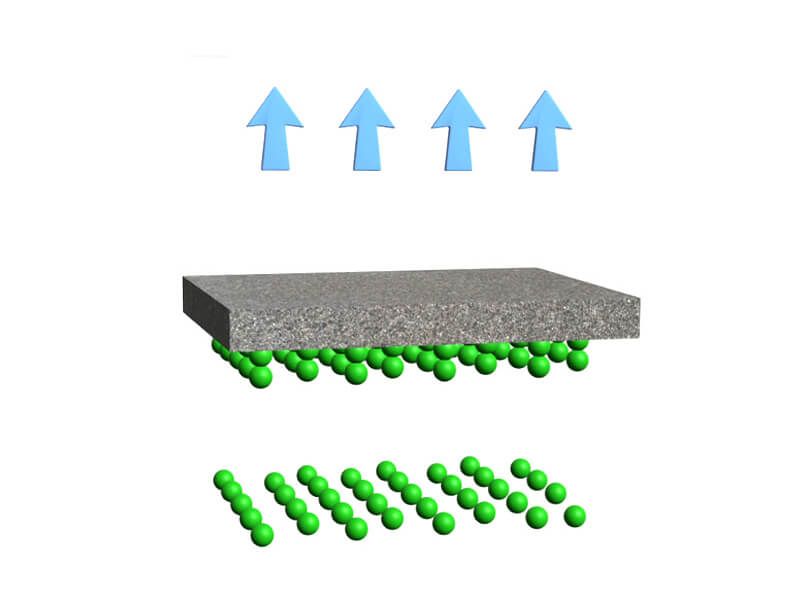

A negative pressure (vacuum) is established across the sintered porous medium. This depression can be used, for example, to particles, which can then be dosed and transferred to a container, requiring the depression to cease. Another application may involve liquid metals which, if subjected to depression during solidification, can better fill mould cavities. The animation shows that the particles are retained on the surface of the filter by the action of the vacuum and are subsequently bottled.

A depression (vacuum) through the porous element draws in a particulate to be dosed, in the encapsulation of drugs, for example. Porous plates (“mirrors”) are also used in aluminium casting moulds to improve fill and minimize defects.

-

Dosing by means of depression and displacement

The photo shows a device that, attached to its upper end, is dipped into a powder. When this happens, a depression is created, causing a certain amount of this powder to adhere to the surface of the lower end where the porous element is embedded. Subsequently, this assembly is moved to a surface on which, after removing the depression, this adhered powder is released for a new processing stage. -

Dosing by means of depression and compaction

The disc on the side is used, for example, in the cosmetics industry, in the production line for compact powder and similar products. In this case, the powder is deposited in a cavity that contains, at the bottom, a porous component. By creating a depression on the opposite face, a certain amount of this powder is dragged into this cavity. Then a scraper is used to remove excess dust. Once this is done, a tablet the diameter of this disc is removed from the cavity and can be manipulated and properly packaged. -

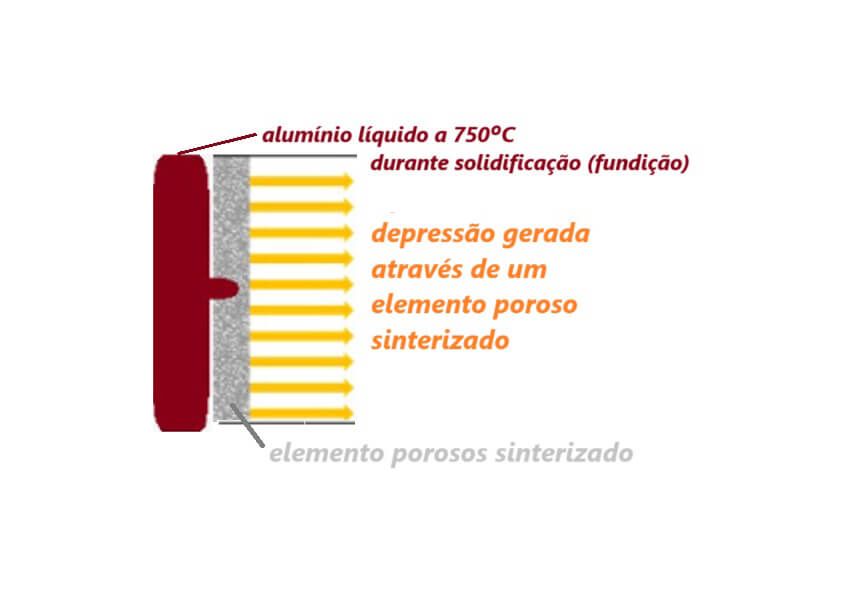

Depression in moulds used in aluminium casting

Porous regions (mirrors) properly positioned in metallic moulds (shells) are useful for improving the filling of liquid metal, particularly aluminium, during the casting stage, especially in the production of pistons. The figure illustrates this application, in which a depression generated through a porous sintered body causes the aluminium to fill in details of the casting, which would not be possible with gravity alone.