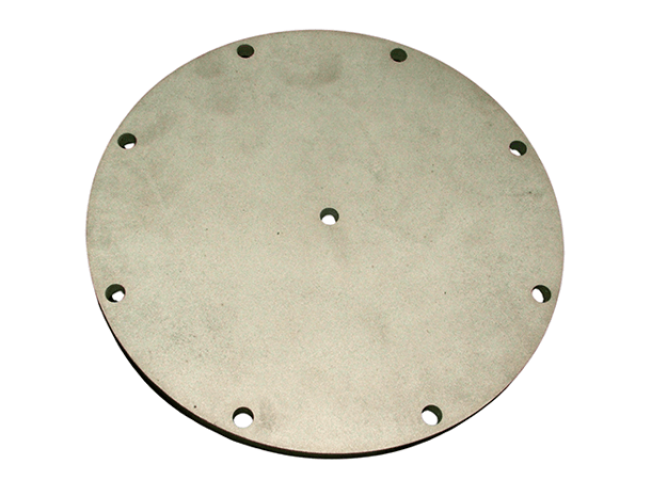

Porous Components

BRATS has some standards for porous components, but as a local manufacturer, it has the versatility to produce on demand. In this way, each application is carefully studied, to establish a relationship between the customer’s needs and the feasibility of manufacturing the component.

Once the conceptual project is defined, the client receives a drawing, so that adjustments and corrections can be made. If necessary, BRATS can produce prototypes for field testing. The company’s proposal is to develop exclusive solutions for each application. The design, materials involved, filter opening (pore size) and manufacturing process can be reviewed to obtain the best performance.

These figures show an example of a porous component. It is a sintered cup mounted on a threaded connection. Although we have some standards, shapes, dimensions and porosity can be adjusted according to the application.

See other products

-

Fluidização

Discos, cartuchos e componentes prontos para o uso em fluidização de pós e particulados em geral, podendo atender o setor de alimentos…

-

Sistemas de Filtração

Sistemas de filtração completos, com elementos filtrantes metálicos (sinterizados) e carcaça. Fabricados em aço inoxidável, atendendo o setor…

-

Cartuchos

Cartuchos (velas), de diversos tamanhos, podendo ser abertos dos dois lados, ou prontos para o uso, contendo flanges e conexões.

-

Componentes Porosos

Componentes prontos para uso, contendo peças porosas sinterizadas e acabamentos, como flanges e conexões. Podem ser produzidos sob demanda

-

Peças Porosas

Peças sinterizadas na forma de discos, cilindros vazados e copos. Diversos tamanhos e porosidades, com aberturas entre 0,5 a 50 micra.

-

Pós Metálicos

Pós metálicos para diversas aplicações: pós de aços inoxidáveis, ferro, níquel, cobalto, molibdênio e carbonetos.