Fluidization & Agitation

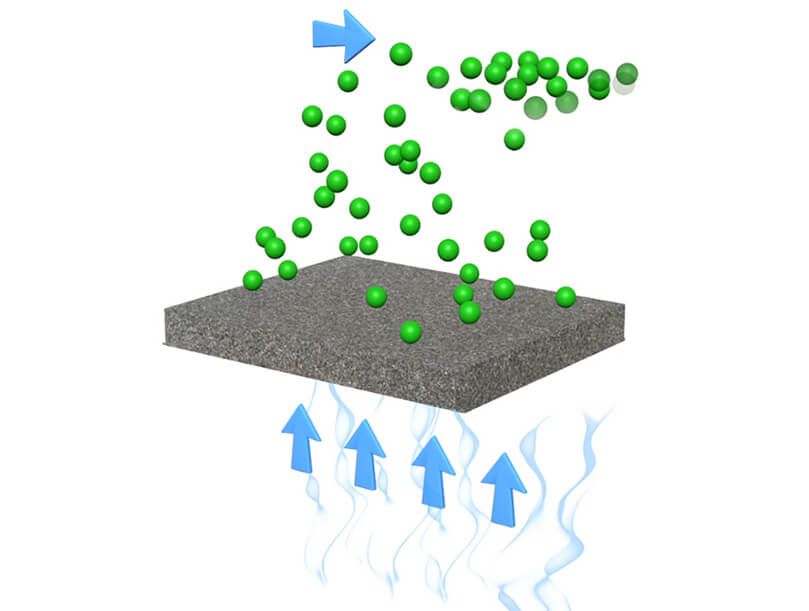

Gas injected through the porous element causes particulate material to acquire fluid behaviour in order to be transported. The animation shows the working principle of fluidization. The injected gas causes the particles to fluidize, that is, to become suspended by the action of the gas. Reactors can use this process, so that a gas can react with the particulates.

The porous element works as a media of injecting a gas, creating turbulence that fluidizes particles, such as coal grains. This process is carried out in reactors or chambers and called “fluidized bed”.

-

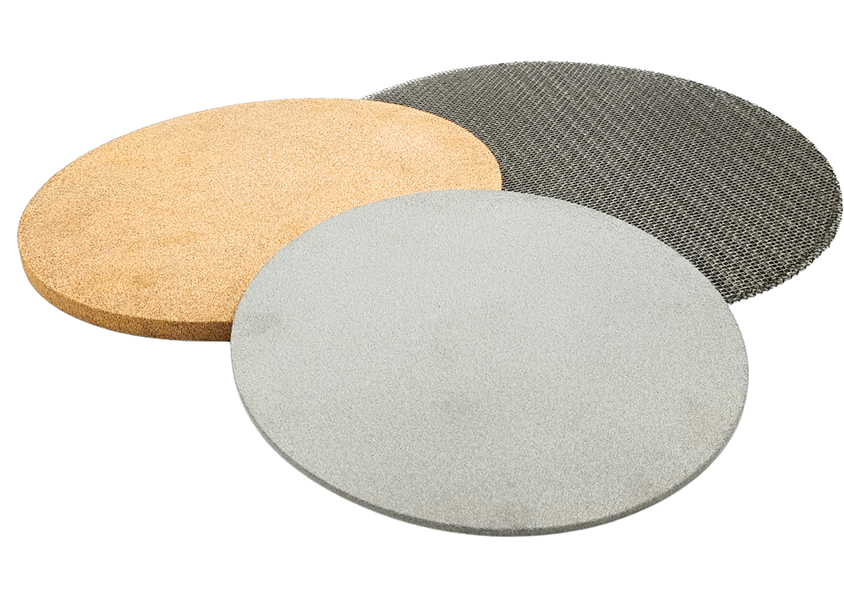

Porous discs for fluidization

Discs such as those function as a support and flow control element in industrial processes, where particulate solids need to be placed in suspension by the action of a fluid (generally air or inert gas). They are commonly used in what is called “fluidized bed”. -

injection of a carrier fluid

This device is used to inject gas, usually nitrogen, into a fluidization system. Its function is to create a positive atmosphere whose function is to drag the already fluidized powder so that it can be channelled. -

Injection of carrier fluid through cartridges

This device is used to inject gas into a fluidization system, with the function of dragging the already fluidized powder. Figure show just another model of the different possibilities used in this function.